This project aims to contribute with the scientific and technologic development and the naval and offshore construction innovation in Brasil, by using advanced techniques of automation and computation, in different steps of the process of constructing a dockyard. The objective will be executed by a multidisciplinar team, envolving the Group of Automation and Intelligent Robotics from FURG, the Program of Oceanic Engineering from UFRJ and the Institute of Economics, Administratives and Accounting Sciences from FURG.

[tabs]

[tab_item title="Team"]

Bruno Quaresma Leonardo - Lattes

Automation Engineer from Federal University of Rio Grande (FURG)

Cristiano Rafael Steffens - Lattes

Master in Computer Engineering from Federal University of Rio Grande(FURG)

Sidnei Carlos da Silva Filho - Lattes

Majoring in Computer Engineering from Federal University of Rio Grande(FURG)

Eduardo do Amaral Leivas - Lattes

Majoring in Computer Engineering at Federal University of Rio Grande (FURG)

Fernando da Fonseca Schneider - Lattes

Majoring in Automation Engineering at Federal University of Rio Grande (FURG)

Jusoan Lan Mór - Lattes

Master's Student in Computer Engineering at Federal University of Rio Grande (FURG)

Marcio Rozante Aguiar - Lattes

Majoring in Automation Engineering at Federal University of Rio Grande (FURG)

Sibyla Andreuchetti Vioto e Silva - Lattes

Majoring in Computer Engineering at Federal University of Rio Grande (FURG)

Valquíria Hüttner - Lattes

Majoring in Computer Engineering at Federal University of Rio Grande (FURG)

Ygor Quadros de Aguiar - Lattes

Majoring in Automation Engineering at Federal University of Rio Grande (FURG)

[/tab_item]

[tab_item title="Project Description"]

- Study of the state of the art in robotics for welding steel plates, especially associated with automation and computing aspects related to perception systems and closed loop control;

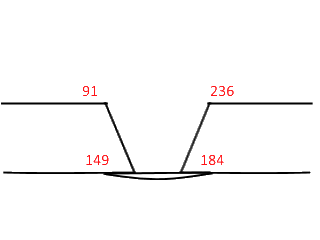

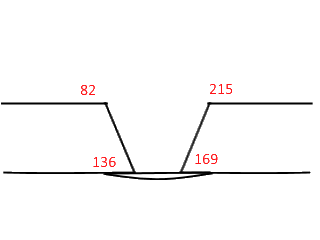

- Hardware design and software development for extracting dimensional characteristics of the groove and development of linear welding robot, adapted to different weld beads;

- Trajectory correction system development capable of performing welding operations with real-time control and closed loop, based on the online perception of the process;

- Testing and validation of robotic tool in shop floor.

[/tab_item]

[tab_item title="Photos"]

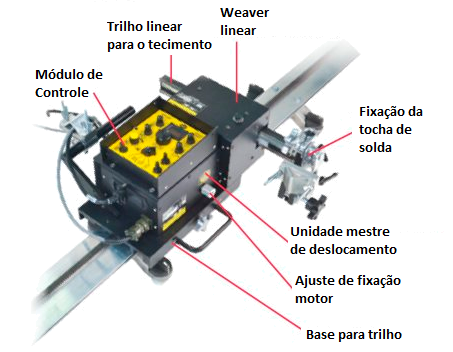

Manual control interface of the Bug-O Matic Weaver robot

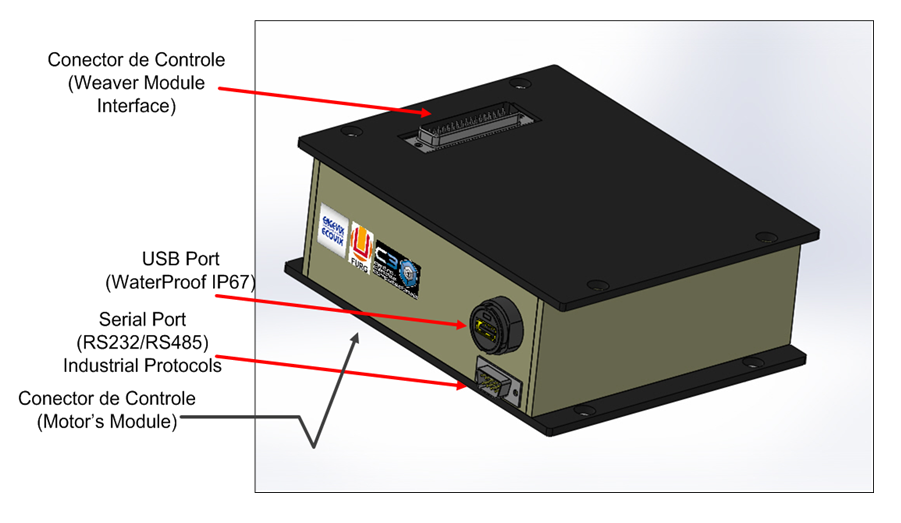

Automated control module robot

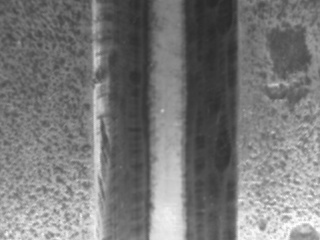

- Robot Initial images

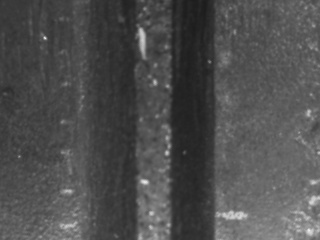

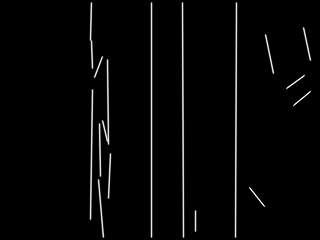

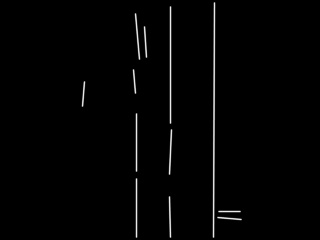

- Processed images

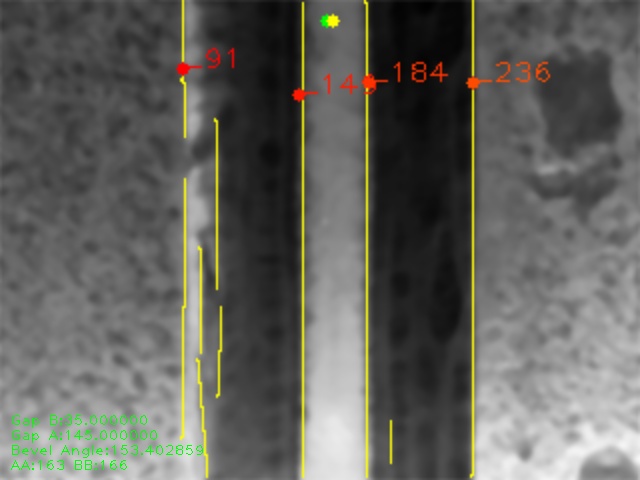

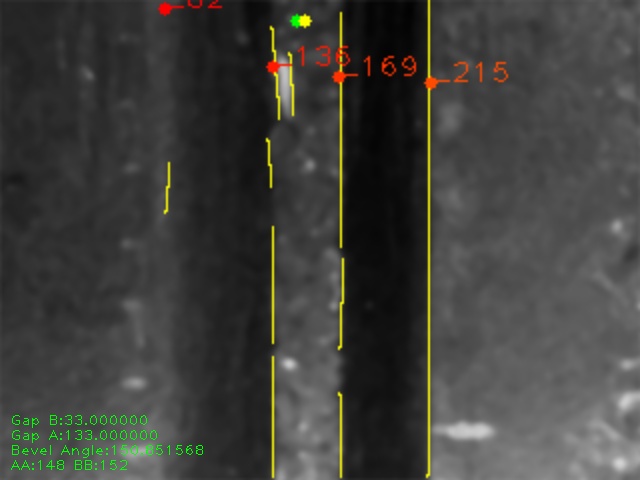

- Results of processing the images

- Results of processing

[/tab_item]

[tab_item title="Papers in Congress Proceedings"]

STEFFENS, C. R.; LEONARDO B. Q.; SILVA, S. d.; HUTTNER, V.; AGUIAR, M. R; LEIVAS, E. d. A.; ROSA, V. S.; BOTELHO, S. S. C. Automated control module based on VBM for shipyard welding applications:Study case on the Bug-O Matic Weaver. In LARS/SBR 2015 I, oct 2015.

STEFFENS, C. R.; LEONARDO B. Q.; SILVA, S. d.; HUTTNER, V.; AGUIAR, M. R; LEIVAS, E. d. A.; ROSA, V. S.; BOTELHO, S. S. C. A VMB System for Intelligent Robotic Welding. In SBAI – Simpósio Brasileiro de Automação Inteligente, 2015.

STEFFENS, C. R.; LEONARDO B. Q.; SILVA, S. d.; HUTTNER, V.; ROSA, V. S.; BOTELHO, S. S. C. Welding Groove Mapping: Image Acquisition and Processing on Shiny Surfaces. In VISAPP, feb 2016.

[/tab_item]

[/tabs]